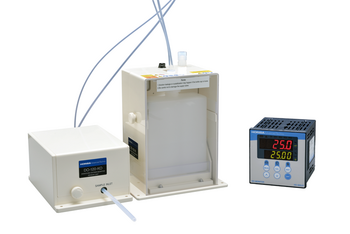

| Product name | Dissolved oxygen meter | ||

|---|---|---|---|

| Model | HD-300 | ||

| Combined sensor | 5505, 5510 (A bipolar diaphragm type polarography sensor) | ||

| Combined probe | DO-1100 | ||

| Measurement range | Dissolved oxygen concentration | 0 mg/L to 20 mg/L (Display range: 0 mg/L to 22 mg/L) | |

| Saturation degree | 0% to 200% (Display range: 0% to 200%) | ||

| Temperature | 0℃ to 50℃ (Display range: -10℃ to 110℃) | ||

| Display resolution | Dissolved oxygen concentration | 0.01 mg/L | |

| Saturation degree | 1% | ||

| Temperature | 0.1℃ | ||

| Performance | Dissolved oxygen concentration | Repeatability | Within ±0.5% of the full scale (response for equivalent input) |

| Linearity | Within ±0.5% of the full scale (response for equivalent input) | ||

| Temperature | Repeatability | ±0.5℃ (response for equivalent input) | |

| Linearity | ±0.5℃ (response for equivalent input) | ||

| Transmission output | Output type | 4 mA to 20 mA DC: input/output isolated type | |

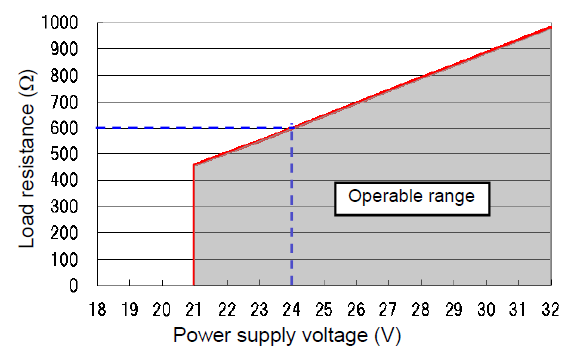

| Load resistance | Maximum: 600 Ω(when power supply voltage is 24 V DC) (*1) | ||

| Linearity | Within ±0.08 mA (output only) | ||

| Repeatability | Within ±0.02 mA (output only) | ||

| Output range | Dissolved oxygen concentration: Selection from preset ranges or free range input within measuring range. | ||

| Occasional out for error | Hold or burnout to either 3.8 mA or 21 mA | ||

| Transmission hold | In the maintenance mode, transmission signal is held at the latest value or preset value. In the calibration mode, transmission signal can be alive or held. | ||

| Contact input | Number of input points | 1 | |

| Contact type | No-voltage a-contact | ||

| Conditions | ON resistance: 40 Ω maximum. Open voltage: 1.2 V DC Short-circuit current: 21 mA DC | ||

| Contact function | External input for transmission holding. | ||

| Temperature compensation | Applicable temperature element | Platinum resistor: 1 kΩ (0℃) (The temperature sensor is built into the probe DO-1000.) | |

| Temperature compensation range | 0℃ to 50℃ | ||

| Temperature calibration | 1 point calibration comparing to reference thermometer | ||

| Calibration | Calibration method | Span calibration in the air or DO saturated aquaous solution | |

| Number of calibration points | Atmospheric calibration: 1 point (Zero electric calibration is carried out automatically) Saturation liquid calibration: 2 points (zero calibration is omitted) | ||

| Additional capabilities | Salinity compensation (0.0% to 5.0%) Automatic detection of calibration failure (Zero error, Sensitivity error) Calibration history (Elapsed days from the last calibration which ever zero or span, zero shift, span sensitivity) | ||

| Self-check | Calibration error | Zero calibration error, sensitivity error, outside of temperature calibration range | |

| Electrode diagnostic error | Sensor error (damage to diaphragm), disconnection of sensor (or damage to sealing), temperature sensor short-circuit, and electric discontinuity of temperature sensor | ||

| meter error | CPU error, CPU error, ADC error, memory error | ||

| Operating temperature range | -20℃ to 60℃ (without freeze) | ||

| Operating humidity range | Relative humidity: 5% to 90% (without condensation) | ||

| Storage temperature | -25℃ to 65℃ | ||

| Power supply | Rated voltage | 24 V DC (operating voltage range: 21 V to 32 V DC)*1 | |

| Power consumption | 0.6 W max. | ||

| Compatible standards | CE marking | EMC :EN61326-1 Class A, Industrial electromagnetic environment RoHS :EN50581 9. Industrial monitoring and control instruments | |

| FCC rules | Part15 Class A | ||

| Structure | Installation | Outdoor installation type | |

| Installation method | Attached to 50A pole or wall | ||

| Protection code | IP65 | ||

| Case material | Aluminum alloy (coated with epoxy-denatured melamine resin) | ||

| Material of fittings | SUS304 | ||

| Material of hood | SUS304 (Epoxy degenerated melamine resin painting) | ||

| Material of window | Polycarbonate | ||

| Display element | Reflective monochrome LCD | ||

| External dimensions | 180 (W) × 155 (H) × 115 (D) mm (excluding mounting brackets) | ||

| Mass | Main body: Approx. 2.8 kg Cover and mounting brackets: Approx. 1 kg | ||

*1: The maximum load resistance that can be connected is decided depending on the power-supply voltage.

Relation between power supply voltage and load resistance

Note

An arrester (spark over voltage: 400 V) is implemented for transmission output, contact input, and communication. However, use a most suitable surge absorption element on the connection lines in accordance with the ambient environment, the situation of equipment installed, and the externally connected equipment.