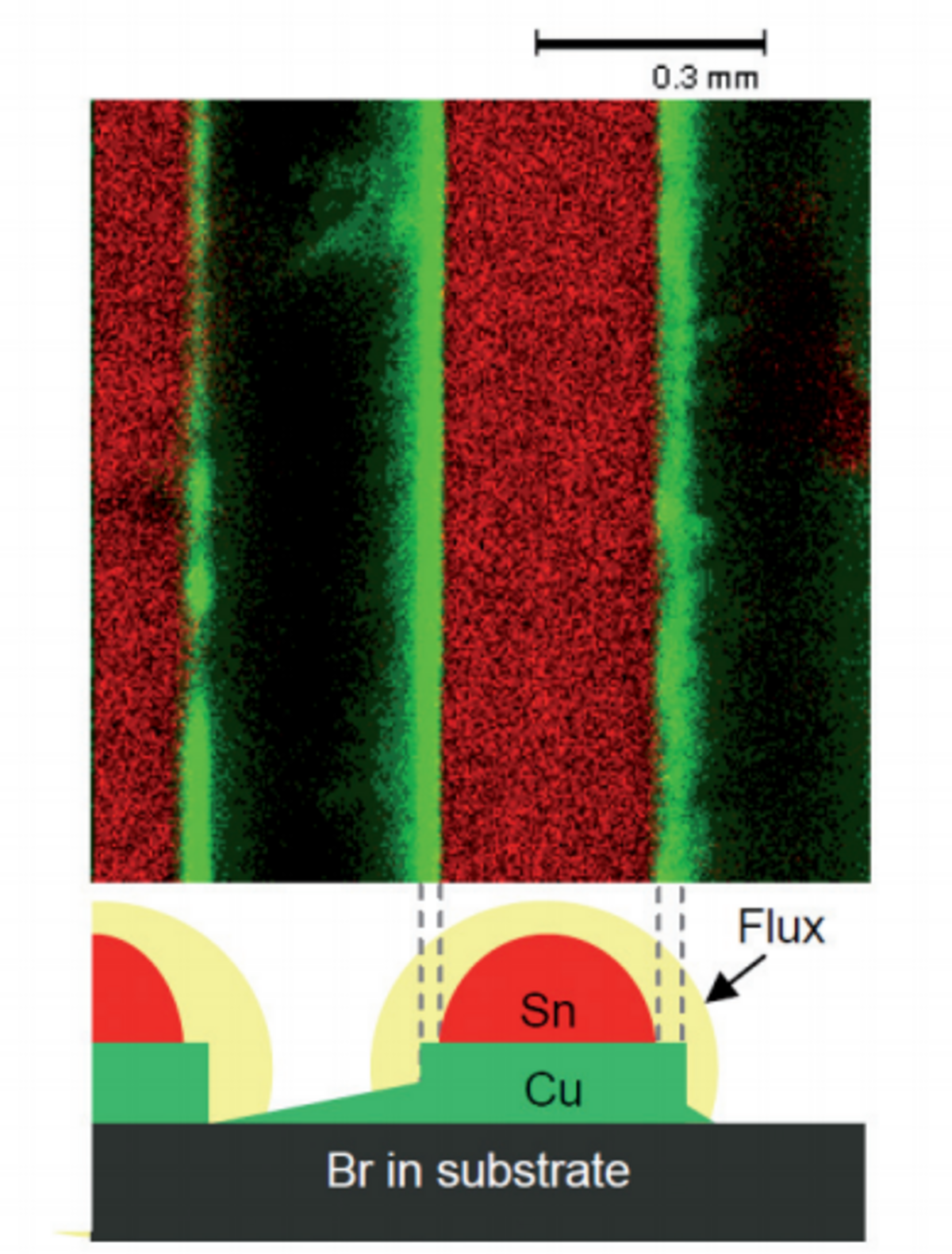

The combination of the XGT-5000’s ground breaking spatial resolution and sensitivity means it is the instrument of choice for fast analysis of electronic components, whether for analysis of restricted harmful elements (the WEEE/RoHS ‘lead free’ legislation), trouble shooting, or R&D. With a beam size of 10 µm even the smallest features on a populated circuit board can be accurately analysed, allowing microscopic contaminants to be identified, wiring/soldering defects to be located, and elemental composition of parts and components to be checked. In addition, the capability for simultaneous XRF and transmission x-ray mapping allows information to be obtained on parts not visible to the eye, for example, circuitry encased in plastic.

Do you have any questions or requests? Use this form to contact our specialists.