<< Back to Raw Materials for Semiconductors

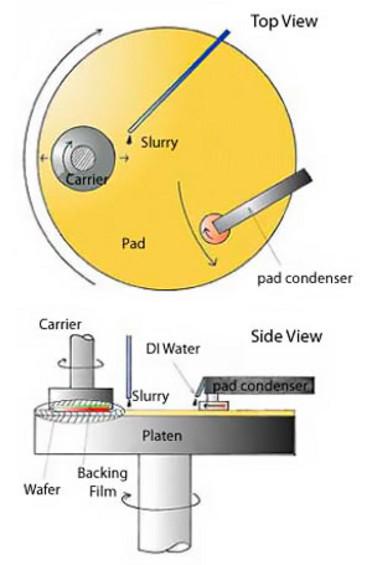

The CMP (Chemical Mechanical Planarization) process is a crucial component of modern multilayer semiconductor manufacturing. Its ability to achieve nanoscale smoothness makes it indispensable, as both die sizes and lithographic techniques continue to shrink. Given the high costs associated with cutting-edge semiconductor device production and the pivotal role of CMP, it is no surprise that abrasive slurries used in the process undergo rigorous characterization.

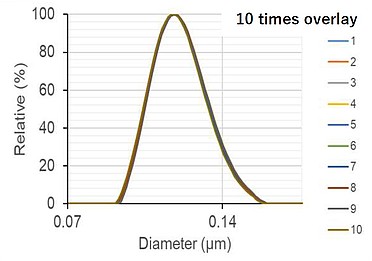

A sub-standard slurry batch can contain particles that are too fine or too coarse, affecting the removal rate, or can contain a few oversized aggregates that cause micro scratches on the wafer surface. CMP slurry manufacturers and users are highly interested in particle size information. This measurement can prevent the loss of millions of dollars worth of wafers by distinguishing good slurry from bad. Good slurry removes material at a consistent rate and uniformly across the wafer, exhibiting predictable performance because of a uniform particle size distribution with excellent stability. Conversely, a low stability slurry can quickly form large particle aggregates, causing irreparable damage to the wafer.

In the future, two major types of CMP slurries using ceria will cohabitate: standard ceria with a particle size of around 100 nm, and nanoceria with a particle size of 10 nm or less. These types of CMP slurries undergo production using different methods. Standard ceria is created by breaking down large particles into smaller ones, while generating particles directly from a liquid produces nanoceria. This production difference influences our analytical requirements. Standard ceria, resulting from the breakdown of larger particles, has a higher concentration. We need to measure these higher concentrations, control particle size during the process, detect the endpoint, and identify any remaining large particles. For nanoceria, lower concentration measurements are necessary, along with information on the number of particles. Process control of CMP slurry is also necessary to ensure product quality.