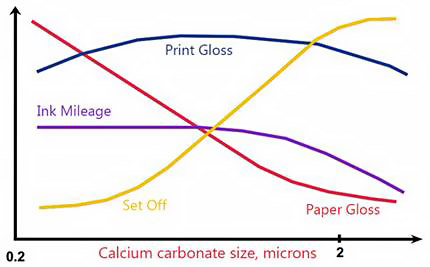

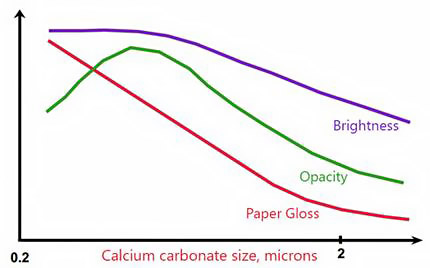

Paper is manufactured from wood fiber slurries, fillers, sizing agents, and coatings. To control certain optical and printing properties of paper, certain materials may be used during the manufacturing process. The particle size distribution of these materials directly affects properties such as gloss, brightness, opacity, color bleed, ink mileage, and more. Selection of the specific sizing agents, fillers, or coatings will depend on the final application for the paper.

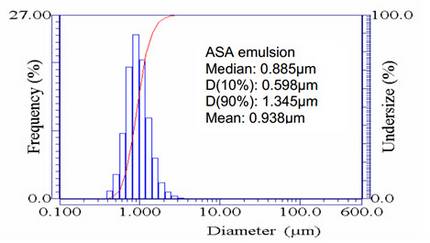

The active ingredient of ASA is an oily monomer. The product is almost always delivered as a light amber oil that must be kept very dry until emulsification. ASA is added to the process in the form of an aqueous emulsion, in which the stabilizer is usually cationic starch and a small amount of surfactant to aid in emulsification. The key goals in using ASA are to avoid hydrolysis and distribute it well in the process. Hydrolysis is minimized by preparing the emulsion as late as possible, usually only seconds before the material is added to the thin stock. Particle size analysis can show whether one has achieved the desired narrow size distribution of droplets, usually with an average size near or below one micrometer. Because of the instability of the emulsion, testing must be done at the point of use.

The HORIBA LA-350 has proven to be extremely popular for this application because of its portability, fast analysis times, and ease of use. The example data shows an ASA emulsion tested in the field. The small size and low weight of the instrument allow it to be transported to various locations for routine testing of the emulsion preparation equipment.

ASA emulsion particle size distribution as measured by the LA-350

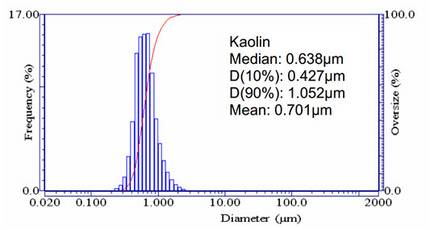

Measurement of particle size can take place at the point of manufacture, such as a kaolin mining plant or pigment factory, or upon receipt at the paper mill as a final check. The example below shows kaolin tested on the LA-350. The size range of interest will dictate the model most appropriate for the application.

Kaolin clay particle size distribution as measured by the LA-350

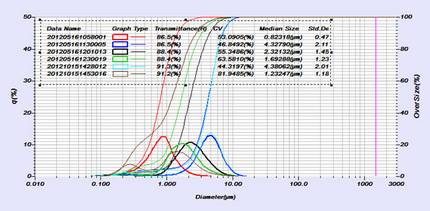

Depending on the application and user requirements, many times the greater capabilities of the LA-960V2 Particle Size Analyzer provide the best solution. One such application is the measurement of calcium carbonate, both ground and precipitated. The addition of a lower wavelength (blue) light source to provide increased resolution for sub-micron materials, the full end-to-end automation, the option to measure dry powders, and the excellent unit-to-unit agreement make the LA-960V2 attractive for this more challenging application.

Various calcium carbonate particle size distributions as measured by the LA-960V2

The LA-960V2 and LA-350 analyzers use laser diffraction technology to provide the fastest, easiest to use particle size results for paper applications. The results are extremely reproducible across multiple operators, multiple units, and multiple locations.

To learn more on laser diffraction, view our webinar: Particle Classroom Series II: The Basics of Laser Diffraction

The LA-350 and LA-960V2 Particle Size Analyzers provide real value to the paper industry through simple, reliable, and portable measurement of fillers and coatings.

Laser Scattering Particle Size Distribution Analyzer

Laser Scattering Particle Size Distribution Analyzer

Do you have any questions or requests? Use this form to contact our specialists.