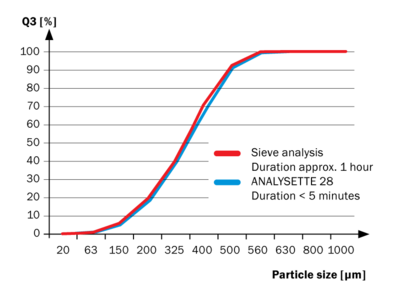

Dynamic image analysis utilizes many of the same steps as static image analysis but sample preparation is completely different since the sample itself is moving during the measurement. Many of the same image processing steps used for static image analysis are also used in dynamic systems, but it is less common that the operator actively selects the functions being utilized. Because of the size range measured by dynamic image analysis, this is a popular technique for applications historically using sieves. By choosing the appropriate size parameters, the results can closely match sieve results while providing the benefits of quick, easy analyses with the bonus information about particle shape.

For conducting frequent sieve analyses, the ANALYSETTE 28 ImageSizer* (available in the Americas) is the ideal, time-saving alternative without the need to calibrate, clean, or replace sieves. Gather both the particle size distribution as well as valuable information about the particle shape in a single instrument.

Comparison of the ANALYSETTE 28 to traditional sieve analysis.

The ANALYSETTE 28* offers all the benefits of an analysis via microscope, but records due to the fully automatic process with up to 75 images per second, a considerably higher number of particles. Instead of just one image, any freely definable number of images can be recorded and evaluated. See the result of the analysis directly without any complicated evaluation just like with a microscope.

With a single high-performance, 5-megapixel industrial camera, the ANALYSETTE 28* covers an extremely wide measuring range (dry: 20 µm – 20 mm / wet: 5 µm – 3 mm ) and ensures the highest resolution of even the smallest particles. In one image, large and small particles can be directly captured, displayed, edited and deleted. A direct USB connection to the computer ensures the fastest possible data transmission for evaluation of the results and the duration of the measurement can be varied depending on the desired number of images (up to 75 images/sec.) or on the number of measured particles.

For efficient dry measurement, the sample material is filled into a funnel and conveyed to the falling chute via the automatically controlled feeder, which its U-shaped cross section ensures a good material feed. There, the sample falls through the measuring chamber between the camera and LED strobe light into an easy to clean sample collecting vessel. The sample remains undamaged and completely intact throughout the entire analysis process. For easy wet measurement, the sample material is fed into a closed liquid circulation system and is pumped with high power through the measuring cell between camera and LED strobe light. The images recorded continuously during these processes offer a variety of evaluation possibilities.

Dry sample collecting tray (left) and Wet Dispersion unit (right) for the ANALYSETTE 28

Dynamic Image Analysis

Do you have any questions or requests? Use this form to contact our specialists.