Latest issue of HORIBA Technical News Letter “e-Readout”

Abstract Testing and evaluation of high-level autonomy features requires large amounts of test data, which is conventionally achieved by driving significant distances on public roads and dedicated proving grounds. The Digital CAV Proving Ground (DigiCAV) is a modular mixed reality co-simulation platform under development in HORIBA MIRA and is a part of our ASSURED CAV ecosystem. Its purpose is to accelerate the development and evaluation of connected autonomous vehicles (CAV) and their subsystems through providing a test environment where different road traffic test scenarios can be orchestrated. The test environment can comprise real and simulated test actors and follows the test-driven development (TDD) methodology.

Click Here to original paper (PDF file)

Introduction

The widespread access to cost-effective computing power, as well as the increasing capability of simulation and modelling tools have allowed automotive manufacturers and their suppliers to increase the proportion of development being done virtually. This has reduced development costs by requiring fewer physical prototypes to be constructed, reduced the real-world testing burden, and allowed more rapid prototype iterations.

While proportionally more development and testing can be done in simulation, the growing complexity of vehicles has, however, increased the overall test burden significantly.

The aim of the DigiCAV platform is to provide an environment for the development and evaluation of CAVs throughout the entire development cycle, ranging from evaluating prototype models in simulation, through testing more integrated hardware or software components, to validating the behaviour of fully assembled vehicles on proving grounds. This is being achieved through a modular platform design with well-defined component-in-the-loop interfaces.

Strong emphasis has been put on co-simulation and component isolation to ensure the intellectual property (IP) of DigiCAV users is protected.

Test driven development for CAVs

Test-driven development (TDD) is a process widely used in the software engineering industry. Its purpose is to increase the quality of the developed software as well as to reduce development costs by increasing the probability that problems are detected early in the product development cycle.

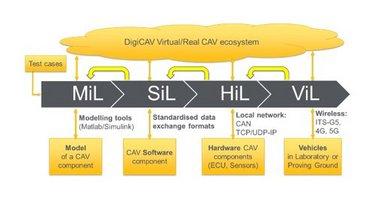

TDD assumes the creation of test cases, which are based on the captured requirements, prior to engineering the desired feature [1]. Vehicle autonomy is a result of interaction between multiple complex software and hardware components, often originating from different suppliers. The DigiCAV platform provides an environment for evaluating CAV components at all stages of development. An example of how such a process could look like is illustrated in Figure 1. The functionality of a new CAV component is modelled in Simulink, which is then connected to DigiCAV for evaluation. The platform simulates a comprehensive CAV environment enabling Model-in-the-Loop (MiL) evaluation of the prototype in various scenarios. It can then be further developed until all the test cases (derived from the requirements) are fulfilled [2]. Following that, the modelled functionality can be implemented as a software and then hardware component (e.g. ECU), which can be similarly evaluated in a software and hardware-in-the-loop (SiL, HiL) environment in DigiCAV. The final evaluation of the system integrated in a vehicle can be performed by bringing the entire vehicle in the simulation loop. This is called vehicle-in-the-loop (ViL).

Model, Software and Hardware in-the-Loop

DigiCAV’s purpose of providing a complete ecosystem for all stages of CAV development is fulfilled by providing the platform users with different kinds of interfaces that allow them to connect their components to DigiCAV for evaluation. The interfaces aim to allow platform users to connect their models, software and hardware to DigiCAV for evaluation using MiL, SiL and HiL simulation.

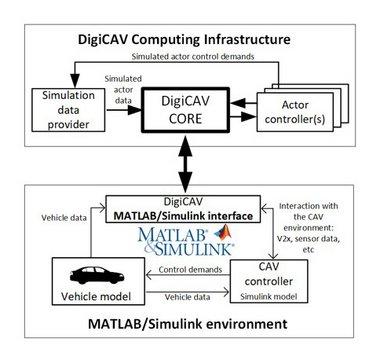

For example, DigiCAV has a MATLAB/Simulink interface to enable real time interactions between a CAV component modelled in Simulink and the CAV driving environment provided by DigiCAV. We have demonstrated this process using a CAV controller implemented as a Simulink model.

This configuration has enabled us to develop and evaluate the performance of the CAV controller using multiple DigiCAV provided test scenarios.

Vehicle-in-the-Loop

Delivering vehicle-in-the-loop (ViL) testing capability on proving grounds (and on dynamometers in the future) is among the primary purposes of DigiCAV. This mode of testing enables customers to evaluate entire vehicles in realistic conditions.

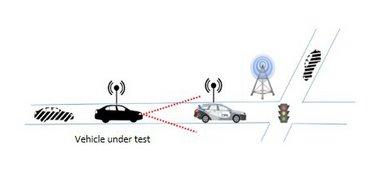

In this configuration, the vehicle under test needs to be either equipped with communication systems enabling it to exchange data with the off board DigiCAV system, or carry sufficient computing power to support running this simulation on board. Both approaches have been demonstrated on HORIBA MIRA’s proving ground.

Here DigiCAV is used in a controlled road environment with a single real vehicle under test and a number of simulated agents that are connected by a wireless network (see Figure 3).

This configuration is mainly intended for fine-tuning and evaluation of decision-making algorithms to maximise energy efficiency in connected cooperative driving environments.

This kind of testing does not present the VUT with any physical targets and will require DigiCAV to directly provide the VUT with data from simulated sensors.

This will require the knowledge of the vehicle’s internal data exchange formats.

Physical test actors

Presenting the VUT with physical test actors is required for full evaluation that includes the on-board sensing and situation awareness. DigiCAV’s ability to provide and manage a mixed reality CAV testing environment, comprising real and simulated test actors, was demonstrated using HORIBA MIRA’s Network Guided Vehicle (NGV).

The NGV is an automated vehicle platform equipped with V2x communication systems capable of automated navigation on proving grounds.

Using DigiCAV the NGV can communicate with other real and simulated vehicles and infrastructure. It can act either as a platform hosting the components under test, such as CAV control algorithms, sensors, sensor data fusion and processing etc, or as an actor for another vehicle-under-test to interact with, as shown in Figure 5.

The NGV is not the only physical actor that can be used with DigiCAV. DigiCAV’s architecture is designed to be vehicle type agnostic, and can incorporate any number and type of vehicles in real, simulated or mixed environments. HORIBA MIRA can produce custom controller plugins for vehicles provided by the customer, and will be adding more of its own physical vehicles that can be hired by the customer.

Example of a mixed reality cooperative traffic scenario

In this example, we demonstrated a cooperative merge scenario in which a real CAV (the NGV) merges with a cooperative platoon of five simulated vehicles at a junction. In this case the components under test were the CAV control modules implementing the cooperative merge behaviour.

The test scenario was visualised using DigiCAV visualisation utility, see Figure 6.

The NGV’s built in Human-Machine Interface (HMI) can be used to configure and initialise the execution of test scenarios. It also allows the safety operator and any other personnel within the vehicle to monitor the progress of the test scenario execution.

The test data is collected using a dedicated data logging component connected to the DigiCAV CORE. This alongside any additional instances of the visualisation utility can be run either from within the vehicle or from any off-board workstation connected to the DigiCAV network.

DigiCAV’s industrial application:

Delivering the capability to assess energy efficiency of automated vehicles – EcoCAR competition

While the DigiCAV platform is still under development, it’s existing feature set has allowed us to use the platform to deliver cutting edge CAV development and evaluation services in the automotive industry. One such example is the use of DigiCAV in the EcoCAR Mobility Challenge.

The EcoCAR Mobility Challenge is a competition managed by the Argonne National Laboratory (ANL) in the USA, in which university teams are tasked with improving energy efficiency of a 2019 Chevrolet Blazer vehicle through applying advanced propulsion control techniques and CAV technologies.

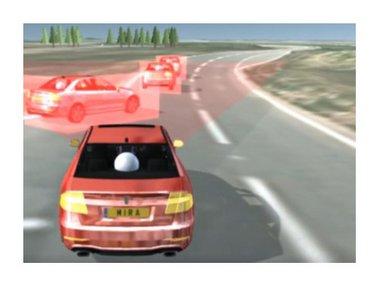

The competition participants’ vehicles will be evaluated for energy efficiency by being made to follow ANL’s test lead vehicle and interact with other simulated vehicles and infrastructure. The competitor vehicles will be evaluated one at a time, requiring accurate and repeatable execution of the scenario for fair comparison. The DigiCAV platform will be used to manage the evaluation process including controlling the lead vehicle, simulating other vehicles and infrastructure, and producing the V2x messages for the VUT to receive (see Figure 8).

EcoCAR tests will be carried out on a dedicated automotive proving ground. The lead vehicle will be made to follow a pre-defined drive cycle, which can be either provided to DigiCAV as a speed profile or recorded while driving the lead vehicle manually.

The vehicle under test will follow the lead vehicle using its on-board sensors and the received cooperative data. Through V2x communication the vehicle under test will gain the advance knowledge of the state of the traffic further ahead. This data will be used to optimise the hybrid electric powertrain of the vehicle under test aiming to reduce overall energy usage [3].

Conclusions

In this HORIBA e-Readout we’ve presented an overview of the DigiCAV mixed reality simulation platform and discussed its use cases. The primary purpose of the DigiCAV platform is to provide customers with a way to accelerate their development of CAVs and their components as well as to simplify the transition between different levels of testing (MiL, SiL, HiL and ViL). DigiCAV’s applications range from evaluating CAV components using in-the-loop simulations to orchestrating multi actor physical test scenarios on proving grounds.

Our platform does not aim to compete with established simulation tools, but to integrate them enabling customers to use already developed software and models and continue using the environments they are familiar with. The capability to integrate with MATLAB/Simulink environment has already been demonstrated and plugins enabling integration with other simulation environments, such as the IPG CarMaker, are being developed.

DigiCAV is part of HORIBA MIRA’s ASSURED CAV ecosystem, which aims to provide the “most complete CAV development and evaluation environment” for industry and policy-makers. While the DigiCAV platform is still under development, several of the key ecosystem components are already in place allowing us to support our partners and customers in their CAV development and evaluation activities.

References

- Ayse Tosun, Ahmed Muzamil, Turhan Burak, and Juristo Natalia. "On the effectiveness of unit tests in test-driven development.“, 2018 International Conference on Software and System Process, 2018.

- Ioannis Kyriakopoulos, Pawel Jaworski, and Stratis Kanarachos. “DigiCAV project: Exploring a Test-Driven Approach in the Development of Connected and Autonomous Vehicles.” In 2019 IEEE International Conference on Connected Vehicles and Expo (ICCVE), 2019.

- Trevor Crain, Pawel Jaworski, Ioannis Kyriakopoulos, Richard Blachford, Brian C. Fabien, “Prototyping EcoCAR Connected Vehicle Testing System Using DigiCAV Development Platform”, 3rd IEEE Connected Automated Vehicles Symposium, 2020

Product & Exhibition information, Contact information

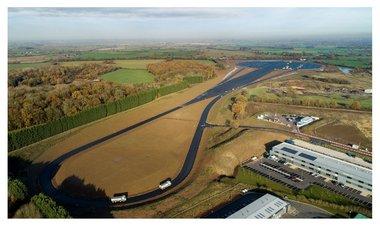

ASSURED CAV is a world-leading connected and automated vehicle test ecosystem. Extending over a 850 acre / 350 hectare site at the HORIBA MIRA campus, it provides the latest facilities to support mobility companies in the design, development and testing of self driving technology.

ASSURED CAV reduces the uncertainty, complexity and time spent in development by providing access to a diverse mix of physical and virtual environments replicating real world scenarios where it is possible to validate the critical challenges of implementing connected self driving technologies to ensure products are safe, secure and robust.

More Information : www.horiba-mira.com/assured-cav/

Upcoming Event (Plans to exhibit):

1. Future Mobility India- 25th Feb- 3rd March

2. 8-10 Jun - Testing Expo Europe 3. 26-28 May - JSAE Yokohama (hybrid)

Upcoming e-Readout issues: Multi-information at the nanoscale for the development of tomorrow’s 2D semiconductors

e-Readout Editorial Office:

Research & Development Division, HORIBA, Ltd.

2, Miyanohigashi-cho, Kisshoin, Minami-ku, Kyoto 601-8510, Japan

E-mail : readout(at)horiba.co.jp

Pawel Jaworski

CAV Innovation Lead, Horizon Scanning, HORIBA MIRA

Ioannis Kyriakopoulos

Advanced CAV Research Scientist, Horizon Scanning, HORIBA MIRA

Richard Blachford

Senior Engineer, Software Engineering EE & CAV, HORIBA MIRA