HORIBA has launched a new virtual-based solution to Real Driving Emissions (RDE) development – which could save businesses up to $17m in prototype vehicle requirements alone.

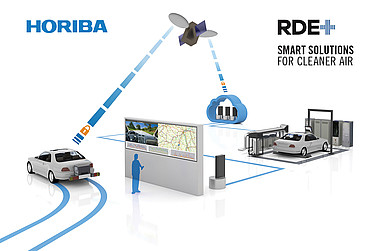

Launched globally today (30 July 2020), RDE+ is a ‘road to rig’ solution that brings the real-world into the laboratory which, when combined with virtual-domain simulation and validation, enables RDE development to be completed more quickly and accurately than before.

The launch coincides with a new white paper commissioned by HORIBA which reveals the growing business case for the virtualization of RDE powertrain development.

According to the study, conducted by Frost & Sullivan, virtualizing RDE testing could help automotive Original Equipment Manufacturers (OEMs) reduce their prototype vehicle requirements up to 75% by replacing on-road testing with more efficient development in the laboratory, resulting in savings of up to $17m per vehicle programme. This is in addition to huge potential savings in reduced testing and development times.

Steve Whelan, Global Development and Application Centre Leader at HORIBA, comments:

“Manufacturers are juggling multiple challenges – emissions reductions, electrification and future mobility, all while remaining competitive. In order to provide a more efficient and cost-effective approach to RDE development, we’ve developed RDE+.

“As demonstrated by our powerful research, this comes as the commercial case for virtual RDE development has never been more compelling – helping OEMs to save up to $17m in prototype reductions on each programme. This is not to mention the cost savings to be had, potentially millions, in development time reductions.”

The launch comes at a pivotal time for the global automotive industry as it seeks to meet the future technology challenge while recovering from the impact of COVID-19. Adding pressure, the report estimates RDE requirements have increased testing times threefold.

Cue a growing need for a more agile approach to product development – says HORIBA.

Steve adds: “The transition to a more agile approach is inevitable in meeting future vehicle demand. Virtual validation will play a lead role in this, enabling products to be developed quicker and better – essentially doing more with less.”

“Manufacturers are advised to take heed now by virtualizing their physical testing activities. As demonstrated by RDE+, with benefits that include reduced prototype requirements, increased confidence and huge cost savings – it will ensure they stay in the fast lane.”

For further information about HORIBA RDE+ offering, please visit: www.horiba.com/RDEplus.