Recently high-accuracy temperature measurement becomes more important in semiconductor and flat panel display (FPD) manufacturing processes. Especially the demand for non-contact thermometer is increasing. However, semiconductor manufacturing equipment uses high concentration reactive gases. These gases make it difficult to measure the temperature with high accuracy and repeatability, because the reactive gases absorb the infrared rays. We have developed the infrared thermometer using an infrared filter through which infrared rays of the wavelength with low reactive gas absorption pass. The influence of the NH3 gas absorption of the infrared thermometer can be significantly reduced. Furthermore, the temperature of the measuring object in the reactive gas can be measured more accurately.

Introduction

Recently high-accuracy temperature measurement becomes more important in semiconductor and flat panel display (FPD) manufacturing processes. Especially the demand for non-contact thermometer is increasing.

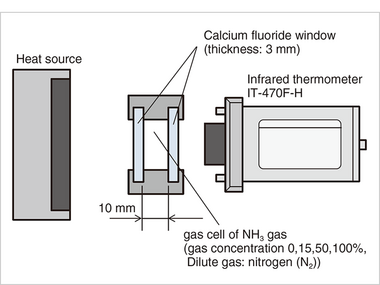

An infrared thermometer, which is one of non-contact thermometers, detects infrared rays radiated from the surface of the object, and it converts them into temperature value. The air between measuring object and infrared thermometer, absorbs infrared rays, therefore, it is necessary to minimize the influence of such absorbance. The spectral characteristics of response of wavelength 8-14 μm light is called “atmospheric window”, where the light shows low absorption with some gases such as water vapor (H2O), ozone (O3), and carbon dioxide (CO2). This spectral response is generally adopted to minimize measurement errors caused by changes in humidity and measurement distance. However, because some semiconductor manufacturing equipment uses high concentration reactive gases that absorb infrared rays, it difficult to measure the temperature with high accuracy and repeatability. In order to solve this problem, we have developed the infrared thermometer using an infrared filter that selectively passes the infrared light in wavelength range with low absorption by such reactive gases.

In this article, we explain the principle of the infrared thermometer and the method of selecting the spectral response condition from the infrared absorption spectrum of the reactive gas. Then we introduce the evaluation results on the influence of infrared light absorption by the NH3 gas with the newly developed infrared thermometer based on HORIBA’s infrared thermometer IT-470F-H for semiconductor manufacturing equipment.

Principle

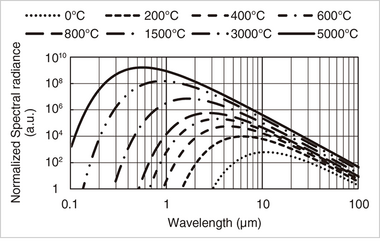

An infrared thermometer can measure temperature of the object without contact detecting infrared rays emitted from the object, and converting an amount of the infrared rays into temperature based on Planck’s law. Planck’s law shows relationship between the temperature of an object and the radiant energy emitted by the object (Figure 1). For example, a heated 800°C iron plate emits red light, and as the temperature rises, it emits white blight light. On the other hand, objects at room temperature do not emit visible light but emit invisible infrared rays. When your hand is brought close to a hot object, you feel warmth before touching it. In the same way, the infrared thermometer measures the temperature of objects by detecting the amount of infrared energy.

Spectral response

An important factor of an infrared thermometer is spectral response. The spectral response is defined over the wavelength region where the infrared thermometer operates. Generally, the spectral response of the infrared thermometer is configured by incorporating an infrared filter.

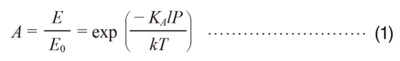

Infrared rays are absorbed by carbon dioxide (CO2), water vapor (H2O), etc. which are contained in the atmosphere. Infrared absorption wavelength differs depending on gas species and modes of molecular vibration of the gas. Absorption of light transmitting through gases can be expressed using Lambert-Beer’s law as follows:

where A: Absorption, E: transmitted intensity, E0: incident intensity, KA: molar attenuation coefficient (cm2/molecule), l: optical path length (cm), P: pressure (Pa), k: Boltzmann constant (m2*kg/(s3*K)), and T: temperature of gas (K).

The gas absorption changes depending on the optical path length, temperature, and pressure. In the case of an infrared thermometer, the optical path length is defined as the distance between the infrared thermometer and the object. This distance varies depending on the application. If the selection of spectral response is incorrect, the temperature of the object can’t be measured correctly due to the gas absorption. Specifically, when absolute humidity changes depending on the season, the measured temperature changes. Therefore, the infrared thermometer of spectral response of 8-14 μm is often used because of its relatively small error caused by infrared absorption through gases.

Temperature measurement of the objects in the reactive gas atmosphere

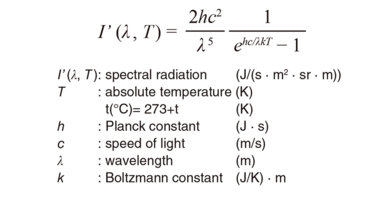

Semiconductor manufacturing process uses several high concentration reactive gases, so it has been difficult to measure temperature with high accuracy due to absorption of infrared rays by these reactive gases in the process equipment. The transmission spectrums of representative reactive gas are shown in Figure 2. The calculation conditions are 1 atm ambient pressure, 25°C gas temperature, 10 mm optical path length, and 100% gas concentration.

From these transmission spectra, it is necessary to select a wavelength region with relatively few absorption peaks. In the case of ammonia (NH3) gas, candidates of no large absorption wavelength regions are 3.5-5 μm and 7-8 μm. In these wavelength regions emitted infrared rays can be hardly affected by gas absorption. In the case of water vapor (H2O), candidates of wavelength region are 3.5-4.5 μ and 8-14 μm. In the case of carbon tetrafluoride (CF4), a candidate of wavelength region is 9-14 μm.

Selection of spectral response based on Planck’s law

In the case of NH3 gas, it is difficult to use the infrared thermometer with “atmospheric window”, because NH3 gas has many absorption peaks in 8-14 μm. There are two wavelength regions with relatively few absorption peaks of NH3 gas: 3.5-5 μm and 7-8 μm. It is necessary to consider not only the gas absorption but also the measurement temperature range and the measurement accuracy in order to select the proper spectral response. Figure 3 shows the relationship between the measurement temperature and the amount of infrared energy at each wavelength. We made a comparison between the results in 3.5-5 μm and 7-8 μm. The results in 8-14 μm is also shown as reference data. Taking the measurement accuracy into consideration, it is necessary to secure a sufficient amount of infrared energy in the measurement temperature range. In the case of the measurement temperature with 0 to 200°C., the spectral response in 7-8 μm is advantageous showing larger energy than that in 3.5-5 μm. And then, in the case of the measurement temperature with 200 to 1000°C., The spectral response in 3.5 to 5 μm is advantageous showing larger energy than the results in 7-8 μm. However, the amount of energy of 3.5-5 μm, sharply decreases for less than 200°C, and the amount of infrared energy can’t be secured sufficiently. In the case of measuring the temperature of the object in the NH3 gas, the spectral response in 7-8 μm is comprehensively considered to be advantageous in order to secure the amount of energy in the range from 0°C to 1000°C.

Infrared thermometer reduced NH3 gas absorption

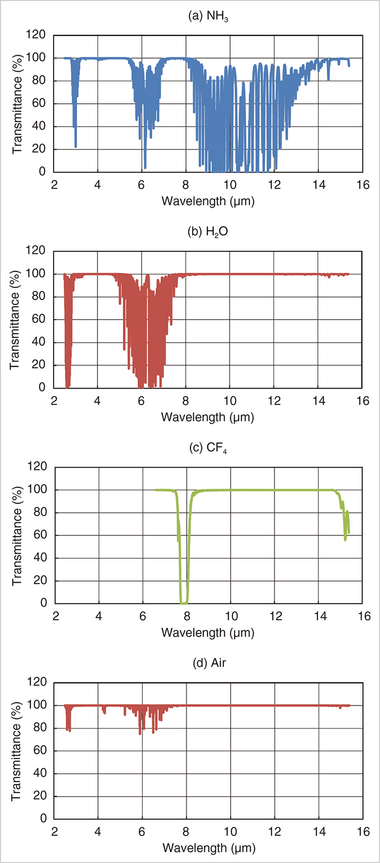

We developed the infrared thermometer based on the infrared thermometer IT-470F-H[1] (Figure 4) on sale in order to reduce the absorption of NH3 gas. We decided the spectral response 7-8 μm as described above.

The experimental setup is shown in Figure 5. We evaluated the trend of measuring value change of the infrared thermometer depending on NH3 gas concentration. We measured the value of the infrared thermometer through the gas cells filled with NH3 gas. The NH3 gas concentrations are 0, 15, 50 and 100% at 1atm. The dilute gas is nitrogen (N2). The thickness filled with NH3 gas is 10 mm, which corresponds to the optical path length. The infrared window used for the gas cell is made of calcium fluoride with a thickness of 3 mm. The temperature of the gas cell and infrared thermometer is stable at room temperature. The temperature of the heat source was adjusted so that the measuring value of infrared thermometer is 165°C at a gas concentration of 0% (N2 gas 100%). Two infrared thermometers were prepared using a general 8-14 μm infrared filter and a 7-8 μm infrared filter.

Results of Infrared thermometer reduced NH3 gas absorption

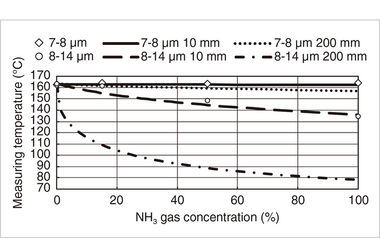

Figure 6 shows experimental results and calculation results of measuring temperature from gas spectrum based on the experimental condition. In the case of 8-14 μm spectral response, the measuring temperature decreased as the NH3 gas concentration increased and decreased by about 20°C at gas concentration of 100%. In the case of 7-8 μm spectral response, the fluctuation between 0% and 100% is within 1°C. These experimental results were in good agreement with this calculation results. It looks that measuring temperature for 7-8 μm spectral response at optical path length 10 mm doesn’t decrease against the gas concentration. On the other hand, when the optical path length is 200 mm, calculation results shows that the measuring temperature of 7-8 μm spectral response is only at about 5°C and the measuring temperature of 8-14 μm spectral response at NH3 gas concentration 100% dropped as much as about 65°C. This is because small absorption peaks appears in 7-8 μm wavelength region due to the optical path length increasing.

The influence of the NH3 gas absorption on the infrared thermometer could be significantly reduced by selecting the spectral response avoiding the absorption peak of the NH3 gas. In addition, it was possible to estimate the measuring temperature by calculation when the optical path length is longer.

Conclusion

We have developed the infrared thermometer using an spectral infrared filter through which infrared rays pass with low reactive gas absorption. The influence of the NH3 gas absorption on the infrared thermometer can be significantly reduced. Furthermore, the temperature of the measuring object in the reactive gas can be measured more accurately. The needs for temperature measurement in a wide variety of gases will increase in the future at not only semiconductor market but also other markets. As we are developing and producing infrared filters and thermopile sensors in-house, we believe that we can propose more valuable solutions that can meet new market needs.

* This content is based on our investigation at the year of issue unless otherwise stated.

References

[1] Readout, 43, 70(2014)

FUJINO Sho

Custom Instruments R&D Department, Product R&D Center 2

Research & Development Division

HORIBA, Ltd.