Specific surface area and pore size distribution are fundamental parameters of many solids. Properties such as porosity, strength, hardness, permeability, separation selectivity, rheology, catalytic activity, dissolution, net density, corrosion, thermal stress resistance, and other physical properties can be directly affected by the porous structure of a material. These properties can be easily investigated using the physisorption or gas adsorption technique provided by the SA-9650 Series of surface area analyzers.

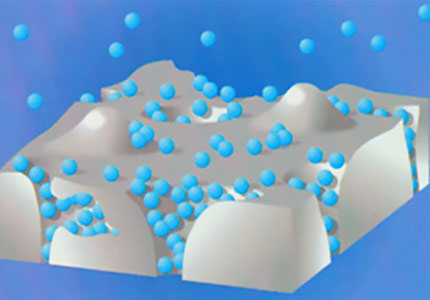

Example of gas molecules adsorbing to a surface.

In nature, all surfaces adsorb water or other vapors to satisfy surface energy. After preparation for gas adsorption, known as “Degassing”, is completed, that surface energy can be used to adsorb probe gas molecules. The volume of gas adsorbed on a surface is recorded and plotted versus pressure. From these raw data, several modelling methods can be used to produce useful results. One of the most frequently used and well known is the BET method, named after the developers, Stephen Brunauer, Paul Emmett and Edward Teller. In essence, the BET method permits the calculation of a “theoretical monolayer” of gas molecules. Knowing the number of moles of gas comprising that monolayer and knowing the cross-sectional area of a single gas molecule permits the determination of surface area. Carefully recording the mass of the sample permits the reporting of “specific surface area” typically in meters squared per gram.

As more gas is adsorbed, layer upon layer of gas builds up on the surface of a material. And if porosity is present, larger pores are eventually filled. Additional models can be used to determine pore size distribution from these data.

Surface pores are divided into three categories by their diameters according to the International Union of Pure and Applied Chemistry (IUPAC). Micropores which are 2 nm and smaller, mesopores which are between 2 and 50 nm, and macropores which are greater than 50 nm.

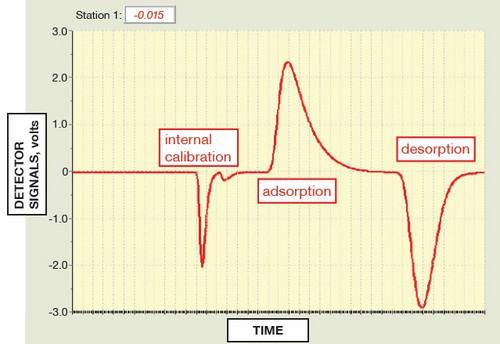

The actual measurement process of physisorption or gas adsorption, requires the sample and sample holder to be cooled, typically using liquid nitrogen, and then exposing the sample to increasing concentrations of nitrogen in a flowing carrier gas – usually helium. As the nitrogen molecules lose thermal energy, the degassed surface energy of the material can adsorb these nitrogen molecules. In a flowing gas adsorption instrument, an automatic calibration is performed followed by an adsorption cycle and then the process is completed by returning the sample to room temperature and a desorption cycle takes place.

Typical single point raw signal of Volts plotted vs Time.

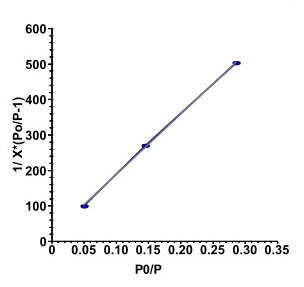

This process can be used one time for a single point measurement, or several times for a multi-point measurement. In general, a surface area result obtained by the multipoint method using nitrogen as the adsorbate may sometimes be more accurate than a single point measurement, but the SA-9650 is built to provide high sensitivity results even with single point analysis. The SA-9650 performs these measurements using the flowing gas method which has several advantages, including high speed of analysis, small footprint, higher reliability as well as lower purchase and ownership costs.

Example of a multi-point analysis.

Whether one chooses to perform single or multi-point measurements with the SA-9650, the process is completely automated requiring that an operator only select an analysis protocol, input sample identifier and sample mass. The instrument and the onboard computer (or if desired, a separate PC) does the rest. The analysis is performed, and results are calculated and displayed and/or printed and saved.

Do you have any questions or requests? Use this form to contact our specialists.

BET Surface Area Analyzers

BET Flowing Gas Surface Area Analyzers