This page introduces key components of Energy Dispersive X-ray Fluorescence Analyzer (EDXRF). The EDXRF analyzer consists of the following key components and the below figure shows a schematic diagram of the most basic benchtop EDXRF analyzers.

Figure. Schematic diagram of a basic benchtop EDXRF analyzer

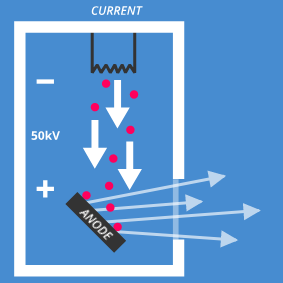

All XRF spectrometers require a source of X-rays, and these are usually provided by an in situ X-ray generator, or, less frequently, by a radioisotope material.

A typical X-ray generator passes an electric current through a filament, which causes electrons to be emitted. These electrons are then accelerated by high voltage (usually somewhere between 20 and 100kV) towards an anode (target). The deceleration of the electrons when they hit the anode causes a broad X-ray continuum to be emitted. This radiation is known as bremsstrahlung (German: braking radiation). In addition, a fraction of the electrons will cause characteristic X-ray fluorescence from the anode material.

Thus, the X-ray emission from a generator will comprise both the broad, relatively weak bremsstrahlung, overlaid with very intense and sharp characteristic fluorescence lines from the target material.

A thin beryllium window is used to allow the X-rays out of the generator, and onto the sample.

The target material, filament current and accelerating voltage all have significant effect on the final output of an X-ray generator.

Target (anode)

The target material is a fixed component of the generator – generators with different target materials are available (eg, Mo, Rh, W), but these are not switchable within a single generator unit. A key part of the generator’s output is formed from the characteristic X-ray Fluorescence of the target material. Since the fluorescence yield increases with atomic mass, increased output at a set voltage/current will be seen by using higher atomic mass target materials. In addition, the energies of the fluorescence lines will vary depending on the material used, and as a result different target materials can result in more or less efficient excitation of particular elements in the sample.

Current

The filament current controls the number of electrons bombarding the target material. As a result, the current directly impacts on the X-ray output intensity for both the bremsstrahlung and characteristic radiation.

Voltage

The bremsstrahlung radiation displays a high energy cut off, since the energy of the radiation cannot exceed the applied voltage. By changing this voltage, the bremsstrahlung cut off (and overall continuum profile) can be modified. The characteristic radiation from the anode material can only be generated when the accelerating voltage (and hence, the energy of the impinging electrons) lies above the absorption edge for that material. Thus, if the voltage is reduced to below the absorption edge, the characteristic line(s) will no longer be present.

As stated previously, a user typically has no control over the target material used in the generator, although generators with different materials are available. However, the tube current and voltage are important variables in an XRF experiment.

The current controls the intensity of X-rays emitted from the generator, and is primarily adjusted to optimize the signal level at the detector.

The voltage has an important effect on the spectral profile of the generator output. With low voltages (eg, 15kV or lower), the bremsstrahlung will be centered at relatively low energies, and the characteristic fluorescence will be restricted to the low energy L (and M) lines. At high voltages (eg, 40kV or above), the bremsstrahlung will be more intense and centered at higher energies, and the characteristic fluorescence will include the high energy K lines of the target material.

The most efficient XRF is stimulated when the incident X-ray beam lies close in energy to the absorption edge in the element(s) in the sample. Thus, by adjusting the generator voltage it is possible to tune, to some degree, the efficiency of fluorescence in the sample.

The energy of the X-ray beam also has an strong effect on the penetration of the X-rays into the sample. The lower the energy, the less penetration. Once again, by adjusting the generator voltage some control is possible over the incident X-ray beam penetration and hence the sampling depth.

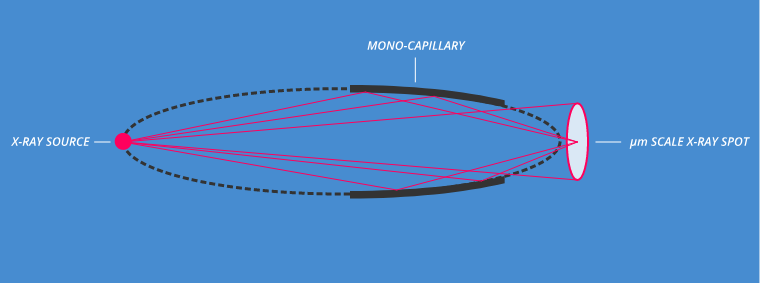

In 1984 a Russian scientist, Muradin Kumakhov, proposed that smooth solid surfaces could be used to form, control, and guide X-ray beams, by virtue of total external reflection. This led to the development of a range of X-ray optics, which can be used to form parallel and focused beams, and transfer X-ray beams with high efficiency.

In a micro-XRF spectrometer it is necessary to generate an intense, narrow X-ray beam. There are two main methods to do this which are summarized below, and will be discussed in more detail in the following pages.

Collimators

The X-rays from the generator are passed through a small aperture usually in the range of a few millimeters down to a few hundreds of micrometers in diameter. The use of collimators for generating narrow X-ray beams is straightforward, but can suffer from loss of intensity as the beam diameter decreases.

Passing a relatively large X-ray beam through a small aperture results in most of the primary X-rays being blocked by the material around the aperture. X-rays only pass through the aperture itself, yielding a beam with a diameter approaching that of the aperture.

However, as the aperture is narrowed, the proportion of X-rays which are blocked increases dramatically. Thus, beams generated in this manner with diameters below 500 µm become low in intensity, and diameters below 100 µm become unworkable because of this problem.

Today collimators are successfully used for high spatial resolution analysis (beam diameters < 20 µm) on synchrotron sources, where the extremely high beamline intensities mean that intensity losses are not an issue. For benchtop instruments with less bright X-ray sources, collimators are not used for ultra-high spatial resolutions.

Mono-Capillary Optics

As Kumakhov discovered, X-rays are very efficiently reflected off glass surfaces when the angle of incidence is low. By producing carefully shaped glass optics it is thus possible to use this total external reflection to focus, collimate and steer X-ray beams.

The solid angle from the X-ray source to the capillary is relatively large, which means that coupling between the two is efficient. As a result, very high intensities of X-rays can be channeled into the capillary, and since reflection itself is very efficient, capillaries can be used to generate high intensity micro-beams with diameters as small as 10 µm. The HORIBA X-ray guide tube (XGT) is an example of the successful use of mono-capillaries, and indeed is unique in allowing 10 µm spatial resolution on a bench top system.

In addition to their intensity, beams generated with mono-capillary glass optics display near perfect collimation, making them ideally suited for micro-XRF analysis.

Poly-Capillary Optics

Kumakhov also showed how capillary optics could be bundled together to form what are called poly-capillary optics. Beams produced in this manner offer benefits in intensity, but they are strongly focused (and hence these optics are often denoted Kumakhov lenses). Focused spots with diameters down to 40 - 50 µm are possible.

For spatially resolved XRF analysis, focused beams are not ideal. X-rays penetrate into the sample (several micrometers through to several millimeters depending on the particular sample), so that although small spot sizes are produced at the focus point, out of focus beams give rise to fluorescent X-rays from much larger analysis areas.

In addition, the focused nature of the beam means that micro-XRF imaging of rough samples is difficult - areas in focus will benefit from small spot sizes, but regions showing a height difference will become blurred due to much larger out of focus spot sizes.

There are a range of detectors available for energy dispersive X-ray spectroscopy. These can be split into three main types:

Solid State Semiconductor

These are usually based around silicon or germanium chips. The X-rays enter through a thin beryllium window, and produce electron-hole pairs in the semiconductor region of the detector. The number of electron-hole pairs formed depends on the energy of the incoming X-ray. The higher the X-ray energy, the larger the number of electron hole pairs. A high voltage is applied to pull the electrons to the back of the detector, where they are collectively recorded as a negative pulse. A multi-channel analyzer (MCA) then counts these pulses, and sorts them into size (which is equivalent to X-ray energy).

To provide acceptable energy resolution, solid state detectors are typically cooled with liquid nitrogen, resulting in typical resolution of < 165 eV.

In many cases this cooling is also vital in maintaining correct dopant dispersion throughout the semiconductor, and warming can cause serious damage to the detector. However, new generations of high purity detectors (for example, the Xerophy™ from HORIBA) remove these concerns, and allow the detectors to be repeatedly temperature cycled as required – cooling is only required whilst detecting.

Silicon Drift Detectors (SDD)

As their name suggests, silicon drift detectors are also based on a silicon detecting element, but the design is somewhat different from the typical solid state detector discussed above. Concentric electrodes are placed on the back surface of the silicon, which are used to steadily pull the electrons (arising from X-ray absorption) towards the center of the chip. As before, the electrons are collected as a negative pulse, and counted by an MCA.

What is different about the SDD is that very good energy resolutions (~ 150eV) can be obtained solely with peltier cooling (typically down to -20 to -30 °C). In addition, multiple incident X-rays can be detected sequentially, since electrons formed by X-ray absorption in different regions of the detector will have different drift times to the anode. As a result, much higher count rates can be tolerated.

In contrast to the solid state detectors, SDDs show relatively poor sensitivity for high energy X-rays.

PIN Diodes

As its name suggests, a pin diode detector uses a much smaller detector element - however as with the two varieties described above, they are typically based on a silicon semiconductor material for the detection. The small size of the semiconductor element allows peltier cooling, but the reduced thickness compromises sensitivity, particularly for the heavier elements.

Do you have any questions or requests? Use this form to contact our specialists.