Abstract

Water quality control systems are essential tools which acts at different level in water management utilities, including industrial process control, environment pollution management and drinking water distribution in agreement with the requirements of standards and regulations[1]. Numerous ways are commonly used to check the water quality and among the existing technologies, online ultraviolet (UV) spectroscopy is one of the interesting technique well known for its reliability, reagent-free method, stability and low operating cost in traditional quantitative analysis[2]. HATFR develops and manufactures fully automated standalone instruments using a rapid measurement approach based on UV spectroscopy to control the quality of water and gas samples. In this paper, HATFR technologies will be described, the advantages and the limitations of the UV spectroscopy for measuring parameters in water and gas sample will be also highlighted in order to provide a full understanding of HATFR products.

Dr. Urelle Biapo

R&D and Technical Support Engineer

HORIBA Advanced Techno France (HATFR)

urelle.biapo(at)horiba.com

Dr. Katsunobu Ehara

Managing Director of HATFR

HORIBA Advanced Techno France (HATFR)

katsunobu.ehara(at)horiba.com

► Click Here for original paper (PDF file)

Introduction

Online UV spectroscopy-based instruments are widely used for water monitoring compared to conventional laboratory techniques because they can quickly capture new even that lead to rapid responses to water quality changes. In order to address demands emerging from surface water applications market, HATFR first product known as UV300 was initially developed and sold for the measurement of nitrates ions which show strong response and good sensitivity by UV spectroscopy method. UV300 Analysers capabilities were then improved by integrating others measuring parameters through a unique modular concept that allow to integrate multiparameter analysis in single instrument. This tuneable configuration feature is possible thanks to the modularity that enable five measurement technologies to be combined in one analyser for the measurement of physical and chemical parameters. Home-made or commercial external sensors can be also connected to the analysers main board for real-time monitoring of physicochemical parameters.

Nowadays, HATFR online water analysers can be customized for various applications such as monitoring process water, drinking water, surface water or wastewater because they can measure from one to sixteen parameters simultaneously. Using the same electronic and software platforms, HATFR develops also gas analysers essentially based on UV-spectroscopy for monitoring emissions from power or coal plants combustion process but also specific gases in chemical industries and refineries.

Modular Concept for Water Monitoring

The five measurement modules which can be integrated on HATFR water products are based on the following methods: UV absorbance (UVA), Nephelometry, Colorimetry, UV Fluorescence and UV spectroscopy after gas stripping. Overall, each parameter corresponds to a specific optical module that can be selected by the user while ordering the analyser, depending on the application. Typically, organic matter (COD), colour, and nitrate ions are monitored by UVA, turbidity is measured using the standardized nephelometry method with an Infrared or Red LASER. Chlorophyl A, Rhodamine, polyaromatics hydrocarbons (PAH) and oil in water (OIW) are detected with the fluorescence module. External probes based on electrochemical or optical methods are mainly used for measuring pH, ORP, turbidity, dissolved oxygen and conductivity. Colorimetry technique is used for orthophosphate ions, iron (II) and other metal ions analysis.

It is well-known that UV spectroscopy measurement follows the Beer-Lamber law which indicates the linear dependency between the absorption of the light and the concentration of the absorbing analyte[2] :![]()

Where, A is the absorbance, L the optical path, C the concentration of the analyte, ε the extinction coefficient.

The HATFR absorbance module is equipped with a xenon flash lamp which is used as light source and either photodiode or full UV-Vis spectrograph are used as photodetector depending on the water instrument model selected. Nevertheless, different flow cells are provided with the analyser depending on the optical paths in order to target different ranges of measurement and applications. Optical path is ranging from 1 mm to 15 mm.

Unique Method for Ammonia and Hydrogen Sulfide

HATFR developed a unique method based on UV spectroscopy after gas stripping for the measurement of ammonium ions (NH4+) and hydrogen sulfide (H2S) in water. Indeed, NH4+ or bisulfide ions (S2-) dissolved in water sample are converted into their corresponding gas NH3 and H2S by addition of small volumes of NaOH 10% or HCl 10%, respectively. The addition of acid and base in water sample is done to meet pH requirements for respective ions conversion. The liquid-gas equilibrium of both NH3 and H2S follows the Henry Law described as follow :![]()

with Ca the concentration of NH3 (or H2S) in the dissolved phase, Cg the concentration of NH3 (or H2S) in the gas phase and H the Henry constant which depend on the gas, the temperature and the liquid sample. The analyser has a preset temperature compensation option to address the variation of sample temperature.

The quantification of H2S gas is made by a dual wavelength method, while NH3 gas quantification is determined using a Fast Fourier Transform (FFT), which ensures high selectivity and reliability of the measurement. H2S shows a wide absorbance band at 200 nm whereas NH3 has a specific periodical UV absorbance spectrum ranging from 190 nm to 210 nm. Compared to existing technologies, there are several advantages of using UV spectroscopy method for ammonium and hydrogen sulfide monitoring in water sample. The interferences of suspended solids, colour or other ionic compounds present in the liquid sample are strongly reduced as the measurement is performed in gaseous phase, only NH3 or H2S gas are stripped out from the liquid reactor to the gas flow cell. In addition, a zeroing is carried out on the filtered air before each measuring cycle aimed to reduce measurement drifts. However, high concentrations of salts such as sea water salt concentration (around 3.5 %) can interfere with both NH4+ and H2S measurement as suggested by the Henry law.

To check the interference of salinity on NH4+ measurement using UV500 equipped with the gas stripping module, water sample containing 0 to 5 % of sodium chloride (NaCl) and NH4+ standard solution (ammonium chloride, 100 ppm) was analysed. This experience aims also to mimic the salinity conditions of sea water which is one of the common requested application for this parameter.

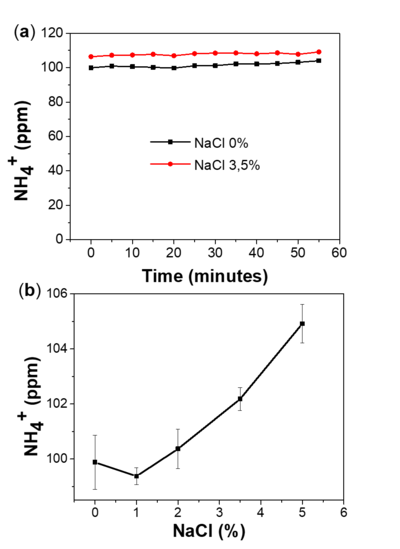

Figure 1 Influence of salinity on NH4+ measurement.

The Figure 1(a) shows the results obtained after a periodic measurement of demineralized water and salty water containing 100 ppm of NH4+. It can be clearly seeing from the results that the sensibility slightly increase by a factor of 1.06 in presence of the NaCl. This behaviour is expected as it is well known that the salinity of the sample influenced the liquid-gas equilibrium and therefore the Henry law.

Figure 1(b) evidences that up to a NaCl concentration of 2%, the salt effect is limited within 1% of the measured value while a NaCl content greater than 2 %, results in a proportional increase of approximately 5% of the reading. However, the repeatability is always within +/- 5% of reading values. This result indicates that NH4+ measurement by UV spectroscopy method after gas striping can be applicable for salty sample such as sea water which is not applicable to ion selective electrode method. Besides, since an increase in salinity will increase the sensitivity of the measurement, it is possible to compensate this effect during analyser factory calibration by adjusting the calibration factor according to the salt concentration. For applications where the salinity of the liquid sample may vary over time, a conductivity probe can be integrated to the analyser to monitor in real-time the salinity value and consequently reduces the overestimation of the NH4+ values by applying a compensation factor to the final readings.

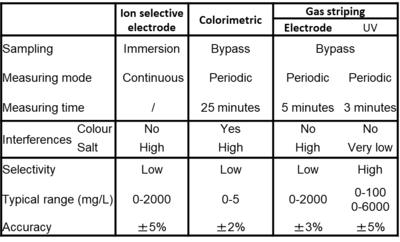

Table 1 Technologies used to measure NH4+ in water based on HATFR investigations.

The Table 1 compared the existing technologies for the online measurement of ammonium in liquid sample. The ion selective electrode is widely used for a blower management of aeration tank in wastewater treatment plant[3]. This method can provide directly immersing in aeration tank and almost continuous measurement. However, ion selective electrode has sometimes drawbacks related to the lifetime of sensor and selectivity for specific ions. Indeed, the sensor usually requires potassium ion compensation to ensure accurate measurements. In addition, sodium ion interferes also the ammonium ion measurement. Therefore, ion selective electrode is hardly applicable to salty sample such as sea water. The selectivity of colorimetric method would be better than ion selective electrode method. However, turbidity and colour due to sample matrix directly interfere the measurement. On the other hand, gas stripping method has a better selectivity and less interference thank to the separation of NH3 gas from water sample. Particularly, the gas stripping UV detector does not need to be in contact with the sample. Out of the listed technologies, the UV spectroscopy after gas stripping appears to be a good compromise in terms of sensitivity, selectivity and response time. Moreover, in UV500 analyser, span drift is greatly reduced as it depends on the optical path that is fixed and on the sample temperature which is automatically compensated in the software.

Gas Analysis by UV Spectroscopy

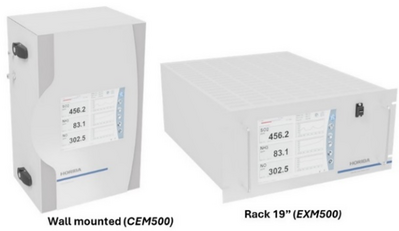

After the development of online-water analysers based on UV Spectroscopy, HATFR extended this technology to gas analysis as certain gases have a typical fingerprint in the UV range. HATFR offers real-time gas analysers which can be wall-mounted (CEM500) or integrated in a standard 19” rack (EXM500), see Figure 2. The main application of this instrument is continuous emission monitoring of power plant or coal plant, essentially targeting NH3, NOx, SOx after combustion process.

Figure 2 HATFR gas analysers embedded in wall mounted enclosure and rack version.

The simultaneous measurement of NH3 and NOx gas is highly requested for DeNOx process in order to keep a vigilant watch on NOx reduction efficiency, catalyst problems, excess/insufficient ammonia injection, and potential maintenance issues from ammonium bisulfate salt formation. DeNOx is the conversion of the two hazardous oxides NO and NO2 to nitrogen and water according to the reaction below :

4NH3 + 4NO + O2 → 4 N2 + 6H2O

Indeed, plants are required to run this DeNOx process to restrict NOx emissions below allowable limits.

HATFR gas analysers can be also used to monitor sulfur content compounds such as H2S, CS2 or other organic compounds like benzene, toluene found in refining process or chemical plants. Nitrogen trichloride (NCl3) which is a specific compound used in the production of chlorine gas can be also monitor using CEM500 or EXM50.

Systems based on UV method has the advantage of fast response time, less interference with water and does not require frequent calibration. These features contribute to the simple sample pretreatment, and are tremendous advantages, as compared to other principles such as Non-Dispersive Infrared Spectroscopy (NDIR) and chemiluminescence detector (CLD). Especially, NDIR has the disadvantage of being fairly slow and insensitive because it is easily influenced by the variation of light source intensity and requiring frequent calibration[4]. Nevertheless, UV spectra generally show broader bands than IR spectroscopy where the peaks are well-defined. This is sometimes a typical drawback of UV spectrum detector. Hence, HAFFR combined the use of different wavelengths, algorithms and adopted a Fast Fourier Transform (FFT) to ensure selectivity while measuring multiple gases simultaneously. For gases with a periodical absorption spectrum such as NH3, SO2, NO, CS2 or acetylene, an algorithm based on FFT guarantees a very good selectivity of measurement. To further improve this selectivity, additional cross-interferences compensation table based on the calculation of an offset and a gain is also available on the analyser settings for each measured gas.

UV spectroscopy presents also other advantages for measuring NH3, NO, SO2 and H2S as the major emissions gases like CO, CO2, CH4 do not interfere with the measured gases because they do not show any absorption in the UV domain. However, H2O has a weak absorption in the UV range but at different wavelengths than combustion gases like NH3, NO, NO2 or SO2. Consequently, H2O, with a usual concentration between 5 % and 20 %, does not affect the measurements. This is also a major difference between UV spectroscopy and other techniques where humidity and natural gases show strong interferences. Nevertheless, the gas composition of the sample must be strictly known to validate each application due to the overlap of some UV spectra measured with HATFR gas analysers. The gas composition should be also compatible with the proprietary algorithms and the selected wavelengths. For DeNOx applications, special algorithms allow to measure NH3 in a 0-10 ppm range with high level of SO2 up to 800 ppm like on coal power plants.

Figure 3 shows the UV spectrum of NH3, SO2 and NO gas in a range of 50 ppm recorded successively with an EXM500. On the other hand, the spectrum of the mixture of the three gases was also measured. The UV spectrum of each gas depicts well-defined structure composed of several peaks that indicate the presence of respectively NH3, SO2 and NO gas. This analysis evidences that the measured gas cannot be clearly distinguish by using directly the UV absorbance spectrum results of the gas mixture as spectra completely overlaps.

Figure 3 UV absorbance spectra of NH3, NO, SO2 (range 50 ppm) and mixture of the three gases measured using standard gas cylinder. Zeroing was performed before each measurement with synthetic air.

By exploiting the periodic structure of absorption spectrum of respective gas, a FFT treatment can be applied to the absorbance data to determine the absorption frequency of each gas. Indeed, the absorbance spectrum can be considered as a sinusoidal electrical signal which is periodic and therefore has a specific frequency. In this case, the FFT processing results in a frequency spectrum that allows to selectively discriminate each gas in a complex mixture using the same analyser.

Gas Analysers Configuration

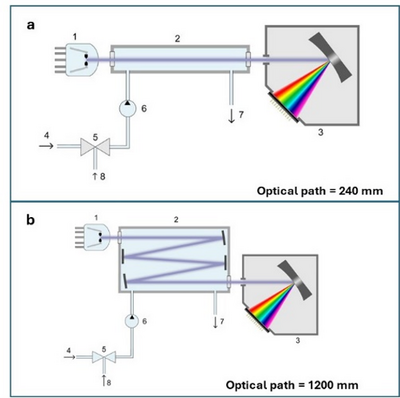

Two types of flow cell are offered depending on the range of the target gas. For the measurement of low gas concentration (0-30 ppm), a flow cell with an optical path of 1200 mm available on the EXM500L model is recommended while a path length of 240 nm is appropriate for monitoring high concentration of gas (0-2000 ppm). The Figure 4 detailed the measurement modules used for each configuration.

Figure 4 (a) EXM500 and (b) EXM500L measurement modules using UV spectroscopy principle. (1) xenon flash lamp, (2) flow cell, (3) Spectrograph (4) sample inlet (5)zero inlet (6) gas pump (7) sample outlet.

The whole gas circuit can be heated and maintained at 190 °C in standard configuration or at 240 °C for specific applications during analysis. The gas measurement is performed at constant temperature and constant pressure thanks to temperature regulation system which ensures a stability of +/- 0.5 °C and the outlet of the analyser which is strictly maintained at atmospheric pressure. The analyser operates in these conditions to avoid a pressure compensation justified by the ideal gas law because a variation of the sample inlet pressure will affect the concentration of the gas in the flow cell. Indeed, the non- linearity of the Beer-Lambert law will induce errors on the measurements if a pressure compensation factor is applied.

Future Development Projects

One of the important feature of HATFR water controller is their tuneable configuration. In comparison to HAT Japan sensors, where each sensor requires a specific transmitter to connect and display the measured values, the EL200 controller from HATFR can handle several analogue and digital probes simultaneously. Further developments will aim to modify the EL200 software and hardware in order to connect several HAT sensors to single controller. Indeed, this function is highly requested, especially for pH self-cleaning electrode from HAT Japan which has unique advantage compared to competitors' probes. The drawback of this electrode is the need for a transmitter for probe connection and another enclosure which handles the power supply necessary for UV LED irradiation. In parallel, we are currently investigating suitable methods to target pathogens and poly or perfluoroalkyl substances (PFAS) in water. The purpose is to develop an online analyser to monitor the microbiological quality of water which is one of the selection criteria for bathing water and surface water during the summer season in coastal area. In the other hand, there is also a huge demand arising for the continuous monitoring of PFAS in water due to their high toxicity to humans and the environment. HATFR works on both topics to contribute to the control of water quality for a sustainable society and thus increase our products portfolio.

Conclusion

HATFR water and gas analysers were briefly described in this paper to give an overview of the technologies used in respective equipment. UV spectroscopy implemented on the analysers has been demonstrated to be an accurate and reliable method which targets different compounds in liquid and gaseous phase. The particularity of water analysers designed by HATFR is their modular concept and their compactness which allow them to be used in various applications. Despite certain limitations of the gas analysis by UV spectroscopy, HATFR gas analysers have the significant advantage of not being interfered by humidity, which make them suitable for analysis of wet gas. Furthermore, they are also suitable for measurement in harsh conditions such as hot and corrosive gas because the gas circuit is made entirely from noble materials.

References

[1] Shi Z.; Chow C.W.K.; Fabris R.; Liu, J.; Jin, B. Sensors, 2022, 22, 2987.

[2] Guo Y.; Liu C.; Ye R.; Duan; Q. Appl. Sci., 2020, 10, 6874.

[3] Akio Ishii, Yuichi Ito, Hiroaki Murakami; Readout No. 43, 2015, 33.

[4] Y.G. Zhang; H.S. Wang; G. Somesfalean, et al., . Atsmopheric Environment, 2010, 44(34), 4266–4271

About HATFR

HATFR offers different models of water analysers including UV500, UV500C equipped with full spectrograph and a simple version UV300. The analyser is also available in ATEX version (UV500 ATEX). EL200, EL300 water controllers and multiple probes are also available in HATFR portfolio. Four models of gas analysers are available : EXM500/EXM500L respectively for high and low range which are the rack versions and CEM500/CEM500L which corresponds to wall mounted versions.

Contacts: saleshatfr(at)horiba.com

HORIBA Advanced Techno France, 100 B Allée Saint Exupery, 38330 Montbonnot Saint Martin, France

Phone: 33 (4) 4-76-86-39, Fax: 33 (4) 76-41-92-27.

e-Readout Editorial Office:

Research & Development Division, HORIBA, Ltd.

2, Miyanohigashi-cho, Kisshoin, Minami-ku, Kyoto 601-8510, Japan